Products

Best-Selling Cartridge Fuel Filter Manufacturers – Air Filter P781102/AF26208 For Donaldson Brand – Raptors

Best-Selling Cartridge Fuel Filter Manufacturers – Air Filter P781102/AF26208 For Donaldson Brand – Raptors Detail:

Product Description

Installation and use of air filter:

1. During installation, whether the air filter and the engine intake pipe are connected by flanges, rubber pipes or directly, they must be tight and reliable to prevent air leakage. Rubber gaskets must be installed on both ends of the filter element; fixed air filter The wing nut of the outer cover of the filter should not be tightened too tightly to avoid crushing the paper filter element.

2. During maintenance, the paper filter element must not be cleaned in oil, otherwise the paper filter element will become invalid and easily cause a speed accident. During maintenance, you can only use vibration method, soft brush removal method (to brush along the wrinkles) or compressed air blowback method to remove dust and dirt attached to the surface of the paper filter element. For the coarse filter part, the dust in the dust collection part, blades and cyclone tube should be removed in time. Even if it can be carefully maintained every time, the paper filter element cannot fully restore its original performance, and its air intake resistance will increase. Therefore, generally when the paper filter element needs to be maintained for the fourth time, it should be replaced with a new filter element. If the paper filter element is broken, perforated, or the filter paper and the end cap are degummed, it should be replaced immediately.

3. When in use, it is necessary to strictly prevent the paper core air filter from being wetted by rain, because once the paper core absorbs a large amount of water, it will greatly increase the air intake resistance and shorten the mission. In addition, the paper core air filter should not be in contact with oil and fire.

4. Some vehicle engines are equipped with cyclone air filters. The plastic cover at the end of the paper filter element is a diversion cover. The blades on the cover rotate the air. 80% of the dust is separated under the action of centrifugal force and collected in the dust cup. The dust reaching the paper filter element is 20% of the inhaled dust, and the total filtration efficiency is about 99.7%. Therefore, when maintaining the cyclone air filter, be careful not to miss the plastic deflector on the filter element.

Product Attributes

| Overall Length | 625 mm (24.606 inch) |

| Largest OD | 230 mm (9.055 inch) |

| Largest ID | 178 mm (7.008 inch) |

| Outside Seal Diameter | 230 mm (9.055 inch) |

| Flow Direction | Outside In |

| Type Seal | Radial |

| Flame Resistant Media | No |

| Primary Applications | NEW HOLLAND 84432504 |

| Secondary Element | AF26207 |

| Warranty: | 3 months |

| Stock situation: | 80 pieces in stock |

| Condition: | Genuine and new |

Packaged Dimensions

| Packaged Length | 35.5 CM |

| Packaged Width | 35.5 CM |

| Packaged Height | 70.5 CM |

| Packaged Weight | 3.1 KG |

Application

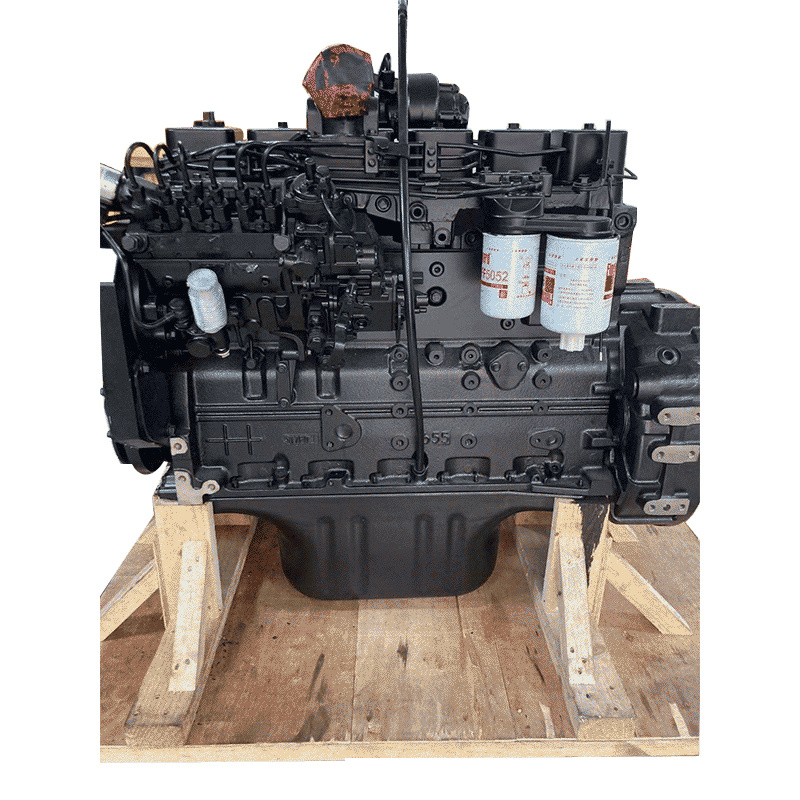

This air filter used in Mercedes-Benz engine, Caterpillar C32 engine and Cummins QSX15 engine for construction, agriculture and mining equipment.

Product Pictures

Product detail pictures:

Related Product Guide:

Along with the "Client-Oriented" small business philosophy, a rigorous high-quality handle system, highly developed producing machines and a powerful R&D group, we always supply high-quality products and solutions, fantastic services and aggressive costs for Best-Selling Cartridge Fuel Filter Manufacturers – Air Filter P781102/AF26208 For Donaldson Brand – Raptors , The product will supply to all over the world, such as: Germany, Amsterdam, Hongkong, Our products are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.