Products

Cheap price Electronic Control Module - Cummins Engine Part Valve Spring 3092508 for Cummins QST30 Engine – Raptors

Cheap price Electronic Control Module - Cummins Engine Part Valve Spring 3092508 for Cummins QST30 Engine – Raptors Detail:

Company Introduction

Raptors, the authorized dealer of Cummins (China), established in 2015 by Mr. Jordan Wang who worked in Cummins (China) for 8 years, Jordan had been responsible for mine market for 4 years during working in Cummins china, so we have big advantages for almost all genuine Cummins generators, engine assembly and spare parts, especially for NTA855, KTA19, KTA38, KTA50, QSK60, QSX15 etc…

Product Parameter

The function of the valve spring

The function of the valve spring is to overcome the inertial force of the valve and the transmission parts during the valve closing process, to prevent the gap between the transmission parts due to the inertial force, to ensure that the valve is seated in time and fit tightly, and to prevent the valve from vibrating when the engine is vibrating. Jumping occurs, destroying its seal. Therefore, the valve springs should have sufficient stiffness and installation preload.

The requirement of valve spring material

Since the valve and valve spring must work in harsh and harsh environments, especially the valve is in direct contact with high-temperature gas, the valve spring must have sufficient rigidity and heat resistance in terms of material. Most of today’s valves are made of JIS SUH3 sintered and hardened special heat-resistant alloy, JIS SUH36 (21-4N) high-grade heat-resistant alloy steel, STELLITE cobalt-chromium-tungsten alloy steel and other materials. Valve springs are mostly made of medium carbon chrome vanadium steel wire or silicon chrome steel wire, so that the spring products have sufficient rigidity and fatigue strength to withstand frequent compression loads and maintain proper elasticity.

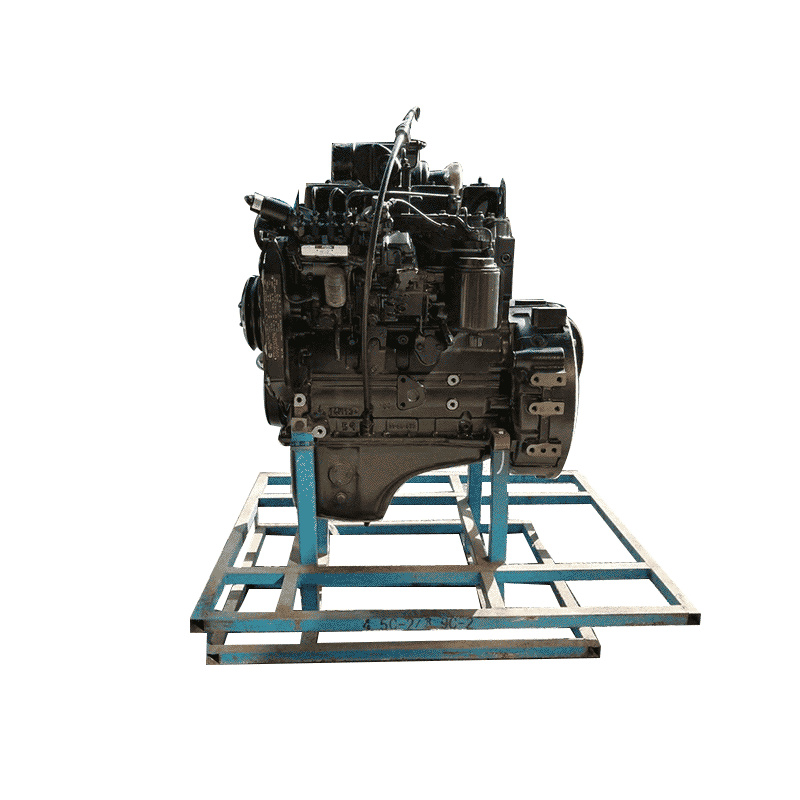

Product Pictures

Product detail pictures:

Related Product Guide:

With dependable high-quality method, fantastic standing and ideal purchaser assistance, the series of products produced by our firm are exported to many countries and regions for Cheap price Electronic Control Module - Cummins Engine Part Valve Spring 3092508 for Cummins QST30 Engine – Raptors , The product will supply to all over the world, such as: Romania, San Diego, Lesotho, With the intensified strength and more reliable credit, we are here to serve our customers by providing the highest quality and service, and we sincerely appreciate your support. We will endeavor to maintain our great reputation as the best products supplier in the world. If you have any questions or comments, please contact with us freely.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!

PRODUCT CATEGORIES

Focus on providing mong pu solutions for 5 years.